News

Voltage generator for medical sector.

MCB Electronics, a leading provider of electrical equipment, recently supplied a cutting-edge voltage generator to a major customer in the medical field. The customer required a reliable and versatile solution for testing medical machines and sterilizers before their market launch. MCB Electronics successfully met this challenge by delivering a high-performance voltage generator capable of meeting specific voltage and frequency requirements.

Meeting Precise Voltage and Frequency Needs:

The customer had two primary needs. Firstly, they needed to test their machines at specific and precise voltage and frequency settings. Secondly, they required a solution to test machines designed for the American market, which operates on a different current standard compared to Europe.

MCB Electronics‘ Customized Solution:

To fulfill these requirements, MCB Electronics provided a state-of-the-art voltage generator with variable frequency capabilities, tailored to the customer’s technical specifications. The complexity of the task stemmed from the diverse nature of the medical products being tested. These products consist of various components, such as motors, compressors, resistors, and sophisticated electronic circuits, all operating simultaneously. This presented a challenge in terms of creating high absorption peaks during different operational phases while simultaneously supplying different types of loads, including resistive, capacitive, and inductive loads exceeding 45 kW. Additionally, each test line had to accommodate up to three sterilizers.

Versatility in Frequency Generation:

In terms of frequency, the generator provided by MCB Electronics offered exceptional flexibility. It could produce a linear frequency range of 40 to 80 Hz [± 1%] or frequencies of 50 or 60 Hz [± 0,01%]. This ensured compatibility with a wide range of medical devices and allowed the customer to conduct accurate and reliable tests across multiple frequency scenarios.

MCB Electronics showcased their expertise and commitment to customer satisfaction by delivering a customized voltage generator that precisely met the unique requirements of their medical industry client. The order was also realized in record time; from order acquisition to shipment of the finished product took about ten weeks. The advanced features and capabilities of the generator allowed for comprehensive testing of medical machines and sterilizers, ensuring their compliance with regulatory standards and smooth market deployment. MCB Electronics continues to be a trusted partner for companies operating in demanding industries, delivering innovative electrical solutions tailored to their specific needs.

Francesco Franco

Understanding Galvanic Isolation: Enhancing Electrical Safety and Performance

Galvanic isolation is a crucial concept in electrical engineering that plays a significant role in ensuring safety, reliability, and optimal performance of various electronic systems. In this blog post, we will delve into the meaning of galvanic isolation, explore why it is called so, provide examples of its application, highlight the key differences between galvanic isolation and electrical isolation, and discuss the custom power conversion solutions offered by MCB Electronics.

What is Galvanic Isolation?

Galvanic isolation is a technique used to separate electrical circuits, preventing direct electrical contact while allowing the transfer of signals or power between them. It utilizes a physical barrier, typically in the form of an isolation barrier or an isolator, to eliminate the possibility of current flow and voltage fluctuations between interconnected systems. This isolation provides several benefits, including enhanced electrical safety, noise reduction, and the prevention of ground loop issues.

Why is it Called Galvanic Isolation?

The term „galvanic isolation“ originates from the concept of galvanic cells, which are electrochemical cells that convert chemical energy into electrical energy. In galvanic cells, two dissimilar metals immersed in an electrolyte create an electric potential difference. Similarly, galvanic isolation separates electrical circuits using a barrier, much like the separation of metals in a galvanic cell, to prevent the flow of electric current and minimize potential differences between interconnected systems.

Example of Galvanic Isolation:

One prominent example of galvanic isolation is its application in AC power sources. For instance, companies like MCB Electronics offer advanced AC power sources equipped with galvanic isolation capabilities. These power sources are widely used in various industries, including telecommunications, medical devices, and industrial automation. By incorporating galvanic isolation, these power sources ensure that the output voltage is electrically isolated from the input, providing an added layer of protection against electrical faults and reducing the risk of electrical shocks or damage to sensitive equipment.

Customized Power Conversion Solutions by MCB Electronics:

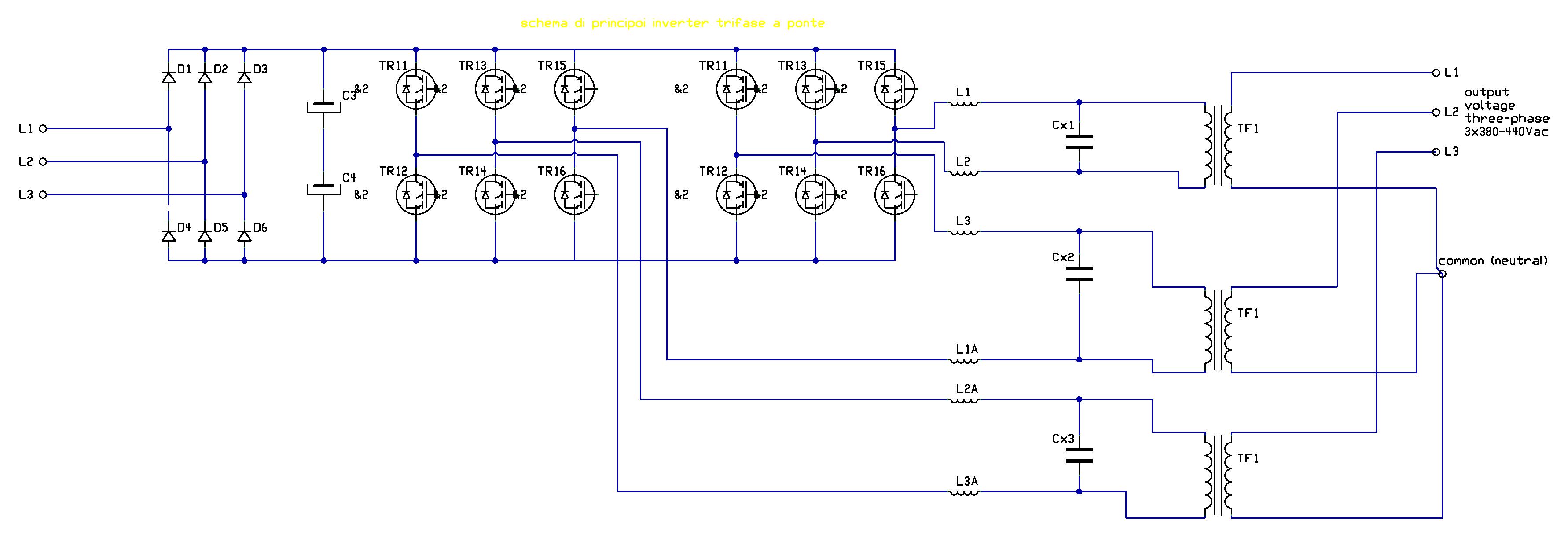

MCB Electronics specializes in producing customized power conversion solutions, offering both autotransformers and isolation transformers. However, when building a three-phase bridge, the transformer becomes mandatory, and there is no choice for an autotransformer. This is due to the design requirements and specific application needs.

Difference between an Autotransformer and a Isolation Transformer:

Differentiating between an autotransformer and an isolation transformer is simple. While both serve the purpose of transferring electrical energy between circuits, the key distinction lies in their configuration. A transformer has no poles in common with the primary and secondary windings, whereas an autotransformer has one pole in common between the primary and secondary windings. This difference impacts factors such as voltage regulation, efficiency, and size considerations.

Galvanic isolation serves as a critical tool for ensuring electrical safety, reducing noise interference, and enhancing the performance of electronic systems. By understanding the meaning of galvanic isolation, its origins, practical applications, and the difference between galvanic isolation and electrical isolation, engineers and professionals can make informed decisions when designing and implementing electrical systems. MCB Electronics, with its expertise in custom power conversion solutions, offers a range of options including autotransformers and isolation transformers to meet specific industry requirements.

Example of Three-phase bridge principle diagram:

Francesco Franco

Understanding Ground Power Units (GPU) for Aircraft: Enhancing Efficiency and Reliability

Ground Power Units (GPU) play a crucial role in the aviation industry, providing essential electrical power to aircraft while they are on the ground. In this article, we will delve into the significance of GPUs, their applications in aviation, their size, functionality, and how they differ from Auxiliary Power Units (APUs). Additionally, we will explore a notable product in this domain, the Power Boost Deluxe.

The Use and Applications of Ground Power Units:

Ground Power Units serve as external power sources for aircraft during various ground operations. They supply electrical energy for crucial functions such as cockpit operations, aircraft systems, and maintenance activities. GPUs are utilized during pre-flight preparations, passenger boarding, engine maintenance, avionics testing, and other ground operations. By using a reliable GPU, airlines can reduce fuel consumption and minimize wear on the aircraft’s internal power systems.

The Size of Ground Power Units:

Ground Power Units come in a range of sizes to accommodate different aircraft types and power requirements. They can vary from compact portable units for smaller aircraft to larger, stationary units designed for wide-body jets. The size of a GPU is typically determined by its power output capacity, which is measured in kilovolt-amperes (kVA) or sometimes in volts and amperes (V/A).

How Ground Power Units Work with Aircraft:

When an aircraft is on the ground and requires external power, a GPU is connected to the aircraft’s electrical system via a power cable. The GPU supplies the necessary electrical energy, enabling the aircraft’s systems to operate without relying on internal power sources like the APU or engines. GPUs typically provide clean and stable power, ensuring the smooth operation of critical avionics systems and minimizing the risk of power fluctuations.

The Difference between APU and Ground Power:

Auxiliary Power Units (APUs) are built-in power sources installed within aircraft. They serve as a secondary power system and can provide electrical power and pneumatic power for various onboard functions. In contrast, Ground Power Units are external devices that supply power to aircraft when they are on the ground. GPUs are connected via cables and offer a reliable and cost-effective alternative to using the APU for ground operations.

The Difference between GPU and APU in Aviation:

While APUs are essential for powering aircraft systems during flight, GPUs are specifically designed to cater to ground operations. GPUs are capable of delivering higher power outputs compared to APUs, making them suitable for heavy-duty operations such as engine starts and maintenance procedures. Moreover, using a GPU instead of the APU for ground power can extend the APU’s lifespan and reduce maintenance costs.

Introducing the Power Boost Deluxe:

One notable GPU product in the market is the Power Boost Deluxe, offered by MCB Electronics. The Power Boost Deluxe is a high-performance GPU that delivers reliable and stable power to aircraft. With its advanced features, including adjustable voltage and frequency settings, overload protection, and user-friendly controls, the Power Boost Deluxe ensures efficient and safe ground operations.

Ground Power Units are indispensable tools in the aviation industry, providing external power to aircraft during ground operations. Their use enhances efficiency, reduces fuel consumption, and minimizes wear on internal power systems. Understanding the importance of GPUs, their applications, and their differences from APUs can help airlines optimize their ground operations. The Power Boost Deluxe stands out as a reliable GPU option, offering advanced features to meet the power needs of various aircraft.

Francesco Franco

Partnership with AtlanTech Marketing LLC

MCB ELECTRONICS and AtlanTech Marketing LLC announce an important strategic partnership and collaboration agreement.

AtlanTech Marketing LLC, as of May 1st 2023, will exclusively represent the MCB Electronics product lines within the State of Florida in the USA.

This agreement follows the meeting held between the parties in Orlando at APEC2023 where AtlanTech showed its interested in the MCB Electronics power conversion solutions.

AtlanTech Marketing LLC, an American company located in Palm Bay, Florida, is a consolidated manufacturing representative company with a wide ranging background and unique perspectives. AtlanTech represents only manufacturers of the highest quality and integrity.

Francesco Franco, MCB Head of Sales and Marketing states: “MCB Electronics designer and manufacturer of innovative solutions in the industrial sector, is excited to harvest the first fruits coming from the major relevant investments in marketing and technical team empowerment undertaken in the past months. APEC2023 was definitely a showcase that attracted the attention of some of the most important stakeholders of the power industry at worldwide level. AtlanTech Marketing LLC could grasp and sense our flourishing potential and we are sure that our cooperation will drive our brand reputation and brand recognition within several industries in Florida. After the touch-down in the West coast back in the end of 2022, it’s now time to pave our way on the East shores of United States”

Timothy Koteff, President of AtlanTech Marketing, LLC adds “We are proud to be trusted to represent MCB Electronics in Florida. We think this exciting and dynamic line will satisfy a wide range of technically diverse companies. We look forward to working with MCB Electronics and their customers.”

Villa Guardia (CO), Italy – 02/05/2023

We released an interview on the e-magazine Easy Engineering Magazine

Villa Guardia (CO), Italy – 01/02/2023

Partnership with LUCENTS TECHNOLOGIES INDIA PVT. LTD

MCB ELECTRONICS and LUCENTS TECHNOLOGIES INDIA PVT. LTD announce an important strategic exclusive partnership and collaboration agreement within the Indian Territory.

LUCENTS TECHNOLOGIES INDIA PVT. LTD, as of 1st November 2022, will be distributing and integrating the new MCB ELECTRONICS product lines into their cutting-edge testing and measuring systems in India with comprehensive solutions suitable with a broad array of markets.

MCB ELECTRONICS based in Italy and active since 1996 designs, manufactures and exports power electronics equipment all over the world with a concept based on strong customization and versatility, covering numerous market applications.

LUCENTS TECHNOLOGIES INDIA PVT. LTD is a leader in extending solutions based products & services in the field of Electronics equipments & TMI systems, having a wide industrial / R&D applications in all the major segments in the market.

This cooperation has been made possible thanks to the incessant scouting of international, qualitative and exclusive partners conducted by our Head of Sales and Marketing Mr Francesco Franco and the long-term vision and forward-thinking of Mr. Anurag Gupta –Director Sales Lucents Technologies to leverage the innovative solutions in the field of Power Electronics from globally reputed brand MCB, Italy to address rising Indian Market.

Villa Guardia (CO), Italy – 01/11/2022