Generatore di tensione per il settore medicale.

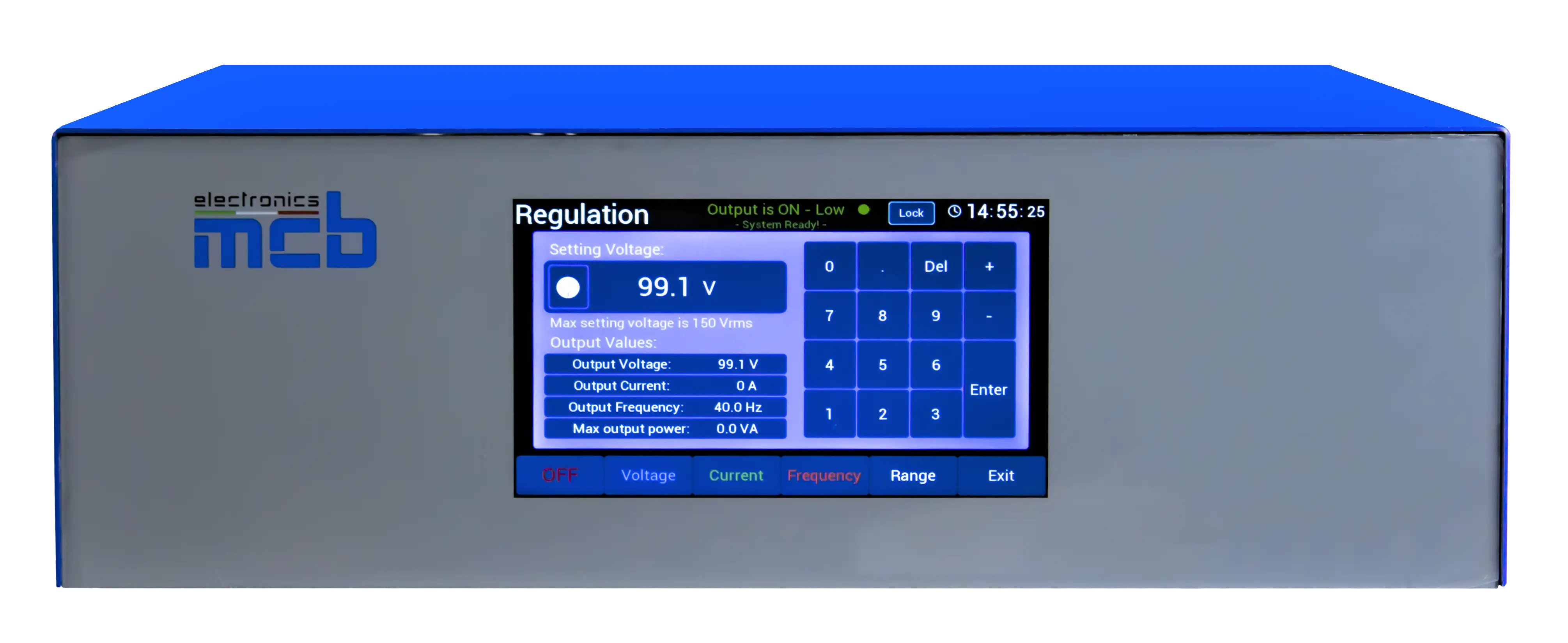

MCB Electronics, fornitore leader di apparecchiature elettriche, ha recentemente fornito un generatore di tensione all’avanguardia a un importante cliente nel settore medicale. Il cliente richiedeva una soluzione affidabile e versatile per testare macchine medicali e sterilizzatori prima del loro lancio sul mercato. MCB Electronics ha affrontato con successo questa sfida fornendo un generatore di tensione ad alte prestazioni in grado di soddisfare requisiti specifici di tensione e frequenza.

Soddisfare precise esigenze di tensione e frequenza:

Il cliente aveva due esigenze principali. In primo luogo, avevano bisogno di testare le loro macchine con impostazioni di tensione e frequenza specifiche e precise. In secondo luogo, avevano bisogno di una soluzione per testare le macchine progettate per il mercato americano, che opera su uno standard attuale diverso rispetto all’Europa.

Soluzione personalizzata di MCB Electronics:

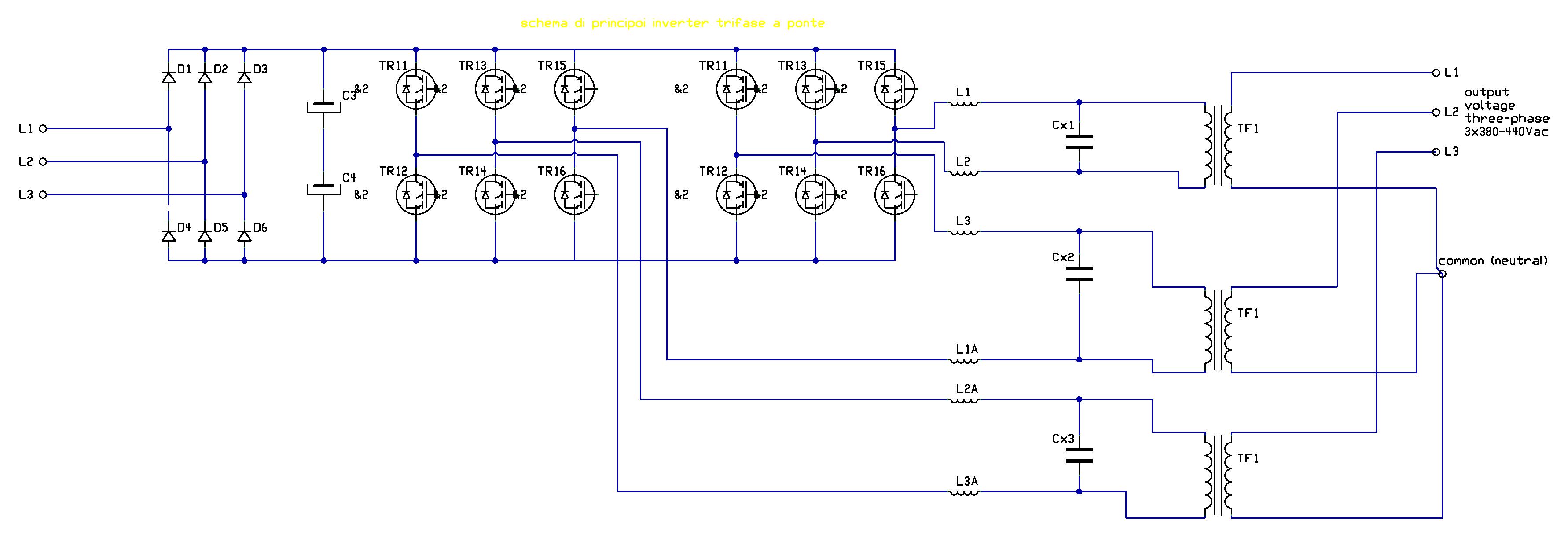

Per soddisfare questi requisiti, MCB Electronics ha fornito un generatore di tensione all’avanguardia con funzionalità di frequenza variabile, adattato alle specifiche tecniche del cliente. La complessità del compito derivava dalla natura diversa dei prodotti medicali da testare. Questi prodotti sono costituiti da vari componenti, come motori, compressori, resistenze e sofisticati circuiti elettronici, tutti operanti contemporaneamente. Ciò ha rappresentato una sfida in termini di creazione di picchi di assorbimento elevati durante le diverse fasi operative, alimentando contemporaneamente diversi tipi di carichi, tra cui carichi resistivi, capacitivi e induttivi superiori a 45 kW. Inoltre, ogni linea di test doveva ospitare fino a tre sterilizzatori.

Versatilità nella generazione di frequenze:

In termini di frequenza, il generatore fornito da MCB Electronics ha offerto un’eccezionale flessibilità. Potrebbe produrre una gamma di frequenze lineari da 40 a 80 Hz [± 1%] o frequenze quarzate da 50 o 60 Hz [± 0,01%]. Ciò ha garantito la compatibilità con un’ampia gamma di dispositivi medici e ha permesso al cliente di condurre test accurati e affidabili in diversi scenari di frequenza.

MCB Electronics ha messo in mostra la propria esperienza e il proprio impegno per la soddisfazione del cliente fornendo un generatore di tensione personalizzato che soddisfaceva esattamente i requisiti unici del proprio cliente del settore medicale. Anche l’ordine è stato realizzato in tempi record; dall’acquisizione dell’ordine alla spedizione del prodotto finito sono passate circa dieci settimane. Le caratteristiche e le capacità avanzate del generatore hanno consentito di eseguire test completi di macchine medicali e sterilizzatori, garantendone la conformità agli standard normativi e una facile diffusione sul mercato. MCB Electronics continua ad essere un partner di fiducia per le aziende che operano in settori esigenti, fornendo soluzioni elettriche innovative su misura per le loro esigenze specifiche.

Francesco Franco