Modular Bidirectional Programmable DC Power Supply

5kW to 1.8MW Output Power

Output Current up to 4500A

AC Input up to 480Vac

Regenerative Load Function

Programmable Sequence Function

Our Regenerative DC Power Supply: Power-GEN

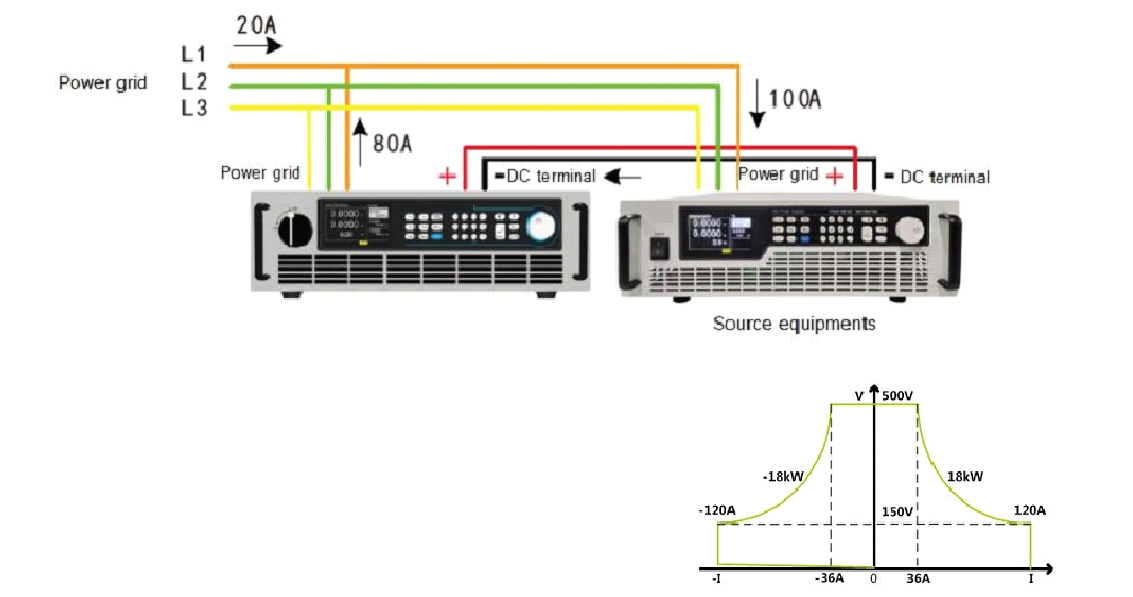

The Power-GEN series is a wide-range high-power bidirectional programmable DC power supply with both DC power supply and regenerative load functions. It can not only realize the source function, but also can be used as a regenerative load to feed the absorbed energy back to the power grid to realize the two-way flow of energy.

The voltage range of Power-GEN series is from 80V to 2250V, the current of a single machine can reach 4500A, and the maximum power of a single machine is 180kW. It can achieve seamless switching between source and load dual quadrants, and has broad test functions and user friendly HMI. It has a wide range of applications in high-power test scenarios such as automotive, renewable energy, high-speed testing, high-power testing etc …

IN A NUTSHELL

- Output power: standalone modules from 5kW to 180kW, parallel up to 1800 kW;

- 18 kW / 3U high power density, standard 19’’ Rack design;

- Output voltage: from 80V to 2250V;

- Output current: up to ±4500A;

- Regenerative load function, regenerative efficiency up to 95%;

- Bi-directional power transfer, seamless switch between sourcing and sinking;

- Power factor 0.99, efficiency > 93%;

- Remote Sensing;

- Adjustable voltage/current slew rate;

- Voltage ramp function; charge/discharge function;

- User programmable sequence function;

- Battery simulator function (optional);

- Support PV array I-V Curve (optional);

- OVP, OCP, OPP, OTP, LVP etc. protection functions;

- CV, CC, CP, CR function;

- CV / CC priority start (prevents voltage or current overshoot with output ON);

- Standard LAN, USB (serial), optional RS485, GPIB or CAN ports;

- Support SCPI, MODBUS, CAN-OPEN (optional) protocol.

Regenerative Load Function

Power-GEN series products have a regenerative load function, which can feed back the energy of the device under test to the factory intranet for direct use, instead of dissipating it in the form of thermal energy. Its energy feedback conversion efficiency is as high as 95%, which can not only greatly reduce the electricity cost of users, but also avoid the use of air conditioners and other refrigeration systems and reduce noise.

Regenerative DC Power Supplies Applications

The typical applications for our Bidirectional DC Power Supplies are industry related, for example:

Battery Packs

In applications involving batteries, thorough testing is crucial during both development and production stages to ensure they meet real-world demands. Traditionally, charging has been executed using a programmable DC power supply, while discharging required an electronic or resistive load. However, modern solutions, such as bidirectional regenerative power supplies, now streamline these processes. This advancement not only conserves capital and rack space but also allows the recovery of energy from a discharging battery back into the local grid. The MCB Power-GEN Series epitomizes this innovation by seamlessly combining both functions as it serves as both a DC source and a regenerative electronic load, offering a comprehensive solution for efficient testing and energy management.

Renewable Energies

Spanning from micro-inverters to commercial solar plant components, the spectrum of solutions ranges from a minimum of 5kW to an impressive 1800kW. Manufacturers are actively crafting solutions designed for seamless integration into the renewable microgrids of the future. These microgrids embrace a variety of solutions, including solar inverters, energy storage utilizing batteries and fuel cells, bidirectional EV/PHEV chargers, wind turbines, and tidal energy.

Electric Motors

The product lines of DC power supplies, electronic loads, and bidirectional power supplies from MCB enable highly flexible and efficient testing. The Power-GEN product series can operate up to 1800kW, providing true autoranging capability. This flexibility allows MCB to generate or reduce the power needed to simulate and test any electrical component in a vehicle, replicating real-world conditions with precision.

Charging Stations

In the realm of electric vehicles (EVs), the pivotal question of charging logistics prompts innovation in the auto industry. As the industry leans towards higher voltages, aiming for smaller currents and reduced copper reliance, the establishment of charging standards remains a work in progress. The range of solutions and performance levels is growing all the time, from wall boxes for private use to high-performance systems for public roads.

Addressing this flux, MCB’s line of DC power supplies with Autoranging capability emerges as a versatile solution.

Do you want to know more about our Regenerative DC Power Supplies? For help, inquiries and customization, Get in touch with us!